Buses and coaches transport thousands of passengers daily, making fire safety a critical concern. In the event of a fire, the consequences can be severe—ranging from serious injury and loss of life to significant property damage. Automatic fire suppression systems play a vital role in detecting and suppressing fires at the earliest stage, thereby reducing risks to passengers, drivers, and vehicles.

In Australia alone, over 500 million bus journeys are made annually. Data from the Office of Transport Safety Investigations indicates that more than 70 bus fires are reported each year. This underscores the growing need for mandatory fire suppression systems in public and commercial transport fleets. Common causes of these fires include electrical faults, wheel and tire failures, and mechanical issues involving oil, coolant, or fuel systems—often associated with turbochargers.

Electrical and Mechanical Failures Bus fires often originate from electrical system malfunctions such as short circuits, faulty wiring, or overheating components—particularly in the engine compartment or near batteries. Mechanical failures, including leaking oil or fuel contacting hot engine parts like turbochargers, are also major ignition sources. Heat and Friction-Related Ignition Overheated brakes, underinflated tires, and other high-friction components can generate sufficient heat to ignite surrounding materials. These risks are exacerbated by continuous operation under heavy load or poor road conditions. Flammable Materials and Cargo Buses are filled with combustible materials—plastics, seat upholstery, insulation, and cargo—all of which can accelerate the spread of fire once ignition occurs. Human and Design Factors Improper maintenance, overloading, and delayed reporting of smoke or unusual odors increase fire risk. Additionally, modern emission control requirements have resulted in hotter engine operations and fully encapsulated engine compartments, which trap heat and reduce ventilation—making early fire detection more difficult for drivers.

Rapid Fire Spread Bus interiors contain flammable materials and confined spaces, enabling fires—often originating in the engine compartment—to spread quickly, reducing evacuation time and complicating suppression efforts. Detection and Suppression Limitations Fires may not be detected early due to limited visibility in enclosed areas. Suppression systems must be compact, fast-acting, and well-maintained to function effectively in tight, high-risk environments. Human Factors Panic among passengers and delayed driver response can hinder evacuation and firefighting efforts. Timely reporting of warning signs is critical to prevent escalation. Operational and Environmental Risks Poor maintenance, fuel or electrical system faults, and external factors like weather or road conditions further elevate the risk of bus fires.

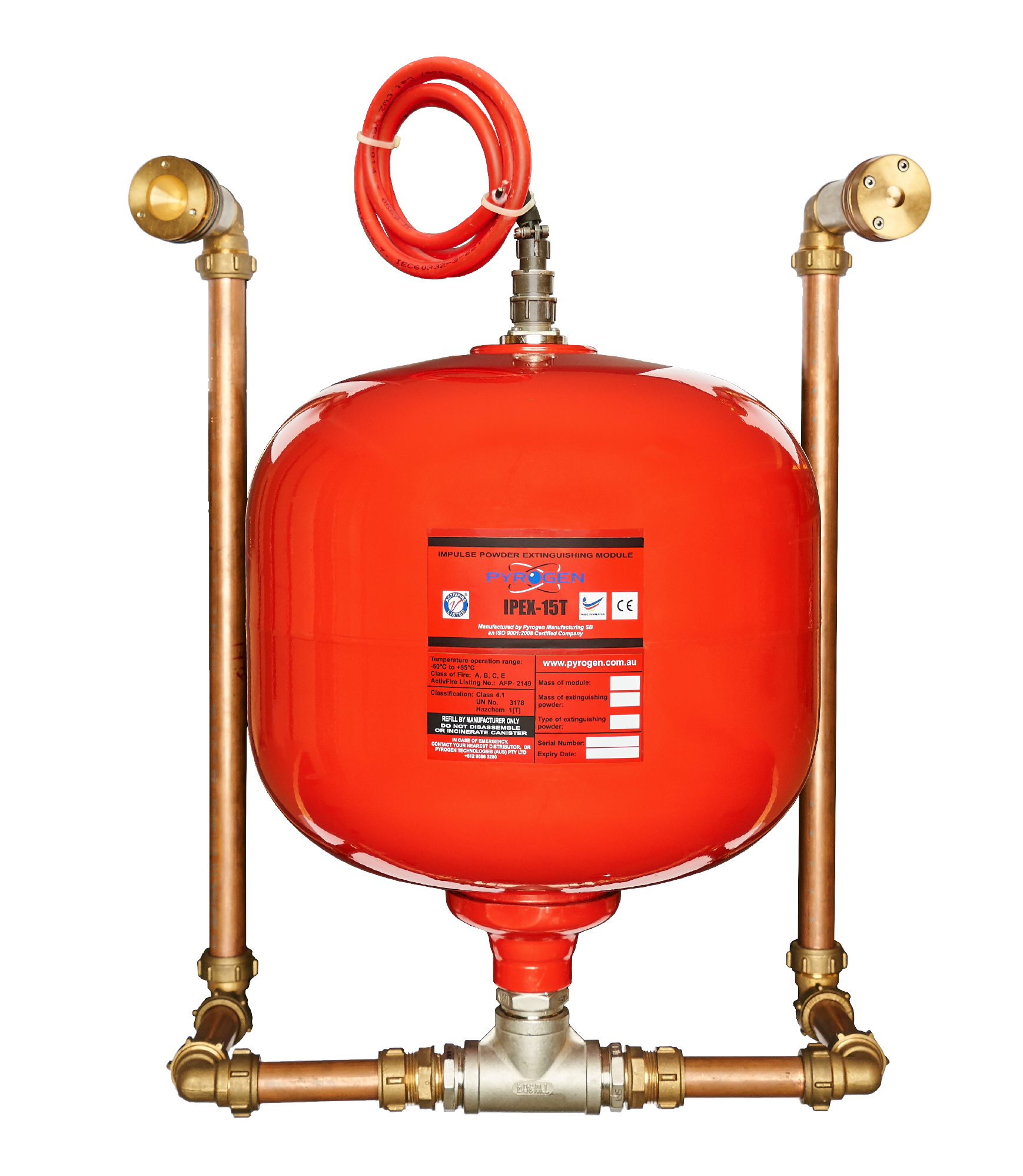

An ideal bus fire suppression system needs to be effective against multiple classes of fire in a semi-open condition, provides rapid extinguishment, able to extinguish spillage fires, require little maintenance, be environmentally friendly and have a small footprint since spaces are limited. IPEX is a non-pressurized fire suppression technology specifically developed to meet the requirements of bus engine bay protection. IPEX’s unique extinguishing powder, powered by an internal aerosol generator with a rapid discharge and high rate of delivery, results in almost instantaneous fire extinguishment. IPEX has numerous benefits for engine bay fire protection:

- Effective even in semi-open conditions

- Able to protect spillage fires (underneath bus)

- Suitable for aggressive environment (high temperature and high vibration)

- Non-pressurized system with no risk of leakages

- Easy installation

- Minimal maintenance required