Electrical control rooms are critical to the infrastructure of any facility, serving as secure environments for housing key electrical equipment. These rooms manage power distribution at various stages—including high-voltage switching in switchgear rooms, voltage step-down in distribution rooms, and final delivery through electrical closets. Their proper functioning is essential for uninterrupted business operations.

However, a fire in any part of this electrical infrastructure can result in severe consequences. In addition to damaging or destroying expensive equipment, such incidents can pose significant safety risks to personnel and cause substantial operational downtime. The financial impact of equipment loss, business interruption, and extended repair times—often stretching from weeks to months—can be devastating.

Faulty Electrical Wiring Malfunctions in electrical systems can result in arc flashes, which generate intense heat and can easily ignite surrounding materials. Overloaded Circuits Prolonged operation under heavy loads—particularly in transformers or other high-capacity equipment—can lead to overheating and fire ignition. Dust and Corrosion Accumulated dust and corrosion, especially in infrequently accessed areas such as distribution pathway rooms, can impair electrical performance, increasing the likelihood of short circuits and fires. Water Intrusion Moisture ingress—due to leaks, condensation, or flooding—can lead to equipment short circuits, even in rooms designed to be moisture-resistant. Electrical Sparks Minor sparks caused by loose connections, aging components, or faulty switches can ignite fires, especially in environments with flammable materials or poor ventilation. Poor Maintenance Aging, neglected, or poorly maintained equipment such as circuit breakers, transformers, or control panels can overheat or fail, significantly raising fire risk. Improper Insulation The use of unsuitable or degraded insulation materials can lead to component overheating and increase the likelihood of electrical fires.

Ventilation ConstraintsVentilation openings are essential for preventing overheating and managing smoke accumulation within generator enclosures. However, these openings pose a significant challenge to fire suppression systems that rely on a fully sealed environment for optimal performance. The inability to contain extinguishing agents within the enclosure can reduce the effectiveness of certain suppression technologies.Fuel Leaks and Ignition RiskDuring generator operation, engine and exhaust components can reach extremely high temperatures. In such conditions, any spilled fuel—whether from refueling or a damaged fuel line—can spontaneously ignite without the need for an external ignition source. This makes fuel leakage a particularly critical fire hazard.Multiple Fire Class HazardsDiesel generators present a complex fire risk profile, as they involve:Class A fires from combustible materials such as wiring and insulation,Class B fires from flammable liquids and gases, including diesel fuel, andClass C fires from energized electrical equipment.As such, fire suppression systems must be appropriately rated and certified to handle all applicable fire classes to ensure comprehensive protection.

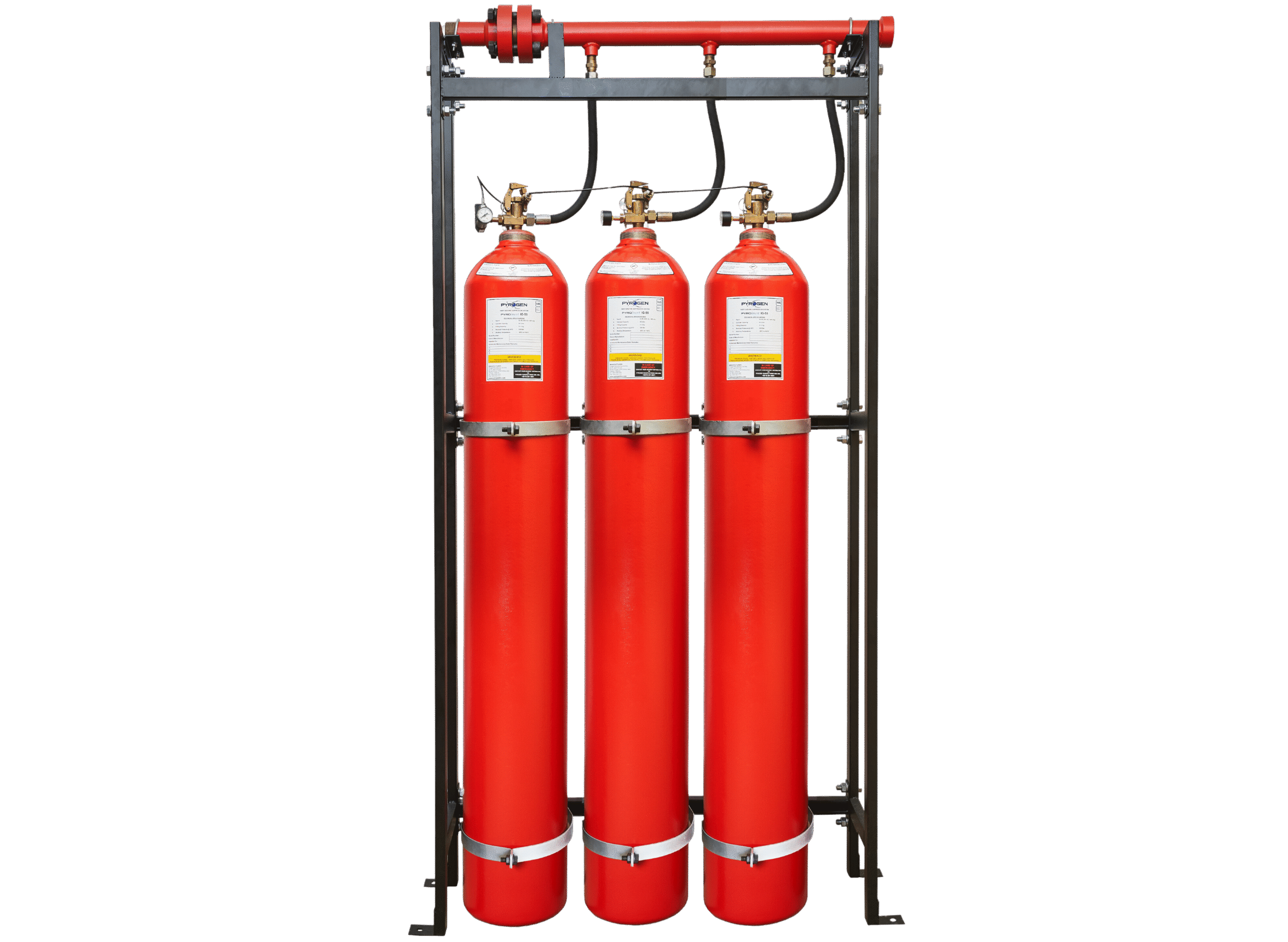

EXA Flexibility of design To protect electrical rooms, EXA condensed aerosol systems can designed with either a Total Flooding system (protection of whole room) or a Direct-to-Source system (protection of equipment at risk). Space saving EXA condensed aerosol generators are compact in size and can be employed to provide comprehensive fire protection from both in-cabinet and external ignition sources. Our smallest EXA model being only 38mm in diameter and 101mm in height, makes the protection of even the most cluttered of electrical cabinets possible. The larger EXA models are ceiling or wall mounted, without the need for additional space to accommodate for the system. Easy installation and maintenance EXA generators are easy to install – requiring no piping or nozzles. Non pressurized and requires no maintenance, EXA aerosol generators provides ‘peace of mind’ protection for 10 years. PYROINERT As a clean agent alternative, PyroInert IG fire suppression systems are widely used to protect electrical rooms by extinguishing fires without leaving any residue and damaging sensitive equipment. Safety for Occupants and Equipment Oxygen levels are lowered to a point that extinguishes the fire but remains safe for human exposure during evacuation. The non-conductive nature of the gases ensures no harm to electrical components. Clean and Environmentally Friendly Inert gases leave no residue, reducing cleanup time, and have zero ozone depletion potential or greenhouse gas effects as they consist of naturally occurring atmospheric elements. Reach out to us to learn more.