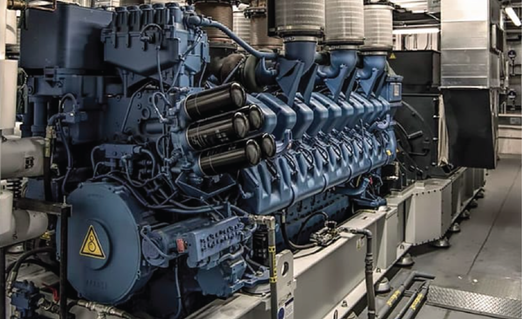

Generators (gensets) play a critical role in providing electrical power to areas without access to the main power grid, including developing regions, remote locations, underground mining operations, military installations, and temporary medical facilities. They are also commonly deployed as emergency, standby, or backup power sources to ensure continuity of operations during grid outages.

Frequent or prolonged power interruptions can severely disrupt mission-critical operations, resulting in productivity losses and reduced profitability. To mitigate this risk, many businesses install natural gas or diesel-powered generators. While effective, these units pose a significant fire risk due to the combustible nature of their fuel and the high operating temperatures of engine components.

Fuel LeakageFuel leaks are among the most common causes of generator fires. They typically result from damaged or defective fuel lines, fittings, or storage tanks. Escaping fuel can easily vaporize and, in the presence of heat or sparks, ignite rapidly—posing serious fire and explosion risks.Electrical Short CircuitsShort circuits occur when electrical current deviates from its intended path due to issues such as faulty wiring, loose connections, or damaged components. This uncontrolled release of electrical energy can produce high temperatures and sparks capable of igniting flammable materials in and around the generator.

Inadequate MaintenanceLack of proper maintenance increases the likelihood of failures that can lead to fire. Clogged filters, degraded fuel lines, and dirty or corroded electrical systems can all contribute to fuel leakage or electrical faults. Scheduled inspections and preventive maintenance are essential to ensure generator safety and reliability.Aging ComponentsOver time, generator components deteriorate due to environmental exposure, mechanical wear, and chemical degradation. Aging materials may crack, become brittle, or corrode—conditions that can cause overheating, spark generation, or fuel system failure, significantly increasing fire risk.

Ventilation Constraints Ventilation openings are essential for preventing overheating and managing smoke accumulation within generator enclosures. However, these openings pose a significant challenge to fire suppression systems that rely on a fully sealed environment for optimal performance. The inability to contain extinguishing agents within the enclosure can reduce the effectiveness of certain suppression technologies. Fuel Leaks and Ignition Risk During generator operation, engine and exhaust components can reach extremely high temperatures. In such conditions, any spilled fuel—whether from refueling or a damaged fuel line—can spontaneously ignite without the need for an external ignition source. This makes fuel leakage a particularly critical fire hazard. Multiple Fire Class Hazards Diesel generators present a complex fire risk profile, as they involve: Class A fires from combustible materials such as wiring and insulation, Class B fires from flammable liquids and gases, including diesel fuel, and Class C fires from energized electrical equipment. As such, fire suppression systems must be appropriately rated and certified to handle all applicable fire classes to ensure comprehensive protection.

With our EXA condesed aerosol fire suppression system, generator sets can be safeguarded against the dangers of fire. 1. Multi Fire Classes EXA aerosol systems are highly effective against Fire Classes A, B & C (according to NFPA10 Classification). 2. Compact and easy to install EXA generators requires no piping and requires much lesser space compared to a pressurized gas system. They can be installed directly within the enclosure, without requiring extra storage room or space. Reach out to us to learn more.