Mobile equipment fire suppression systems are essential to protecting high-value assets and personnel across a wide range of industries, including mining, construction, transportation, logistics, and heavy equipment operations. Whether deployed on off-road mining vehicles, on-road transport fleets, or specialized machinery such as tunnel boring machines or port cranes, these systems are designed to detect and extinguish fires at the source—often before the operator is even aware of the danger.

Despite their varied functions, these machines share one common trait: their substantial capital value. For example, a single tire on a mining haul truck can cost upwards of USD $40,000, while a tunnel boring machine (TBM) may cost up to USD $80 million. More critically, such machinery is often tied directly to revenue-generating activities. The loss of a TBM due to fire could result in project delays where each mile of uncompleted tunnel equates to hundreds of millions in unrealized returns. Similarly, a disabled port crane may halt cargo movement across an entire berth, with cascading economic impacts.

These machines are typically powered by large, high-output engines and rely on complex electrical systems to operate effectively. Yet they are frequently deployed in harsh environments—remote mining sites, rugged terrain, or enclosed industrial facilities—where the risk of fire is amplified and emergency response capabilities are often limited or delayed.

Presence of Combustible Materials Industrial vehicles contain significant quantities of diesel, hydraulic oil, and lubricants—all of which are highly flammable and increase the risk of fire. High Heat Generation Engines, exhaust systems, and braking components operate at elevated temperatures, providing multiple potential ignition sources. Electrical System Vulnerabilities Complex wiring networks, control units, and sensors can develop faults or short circuits, particularly under heavy operational stress. Harsh Operating Conditions Frequent exposure to dust, debris, and vibration accelerates wear and tear on components, increasing the likelihood of mechanical or electrical failure. Limited Emergency Response Access These machines often operate in remote or isolated locations, where immediate fire service support is unavailable—making fast, effective fire suppression critical to minimize losses. These conditions create a high probability for what is termed a “large-loss fire”—a fire that causes extensive damage, not only through equipment destruction but more significantly through prolonged downtime and lost operational revenue.

Importance of Fire Suppression Systems in High-Value Equipment Due to the high value and limited accessibility of much equipment, integrated fire suppression systems are essential operational components, not just safety features. Reliable fire protection is crucial to managing the elevated risk in these environments. Permanent Installation for Immediate Protection These systems must be permanently installed on or within the equipment to ensure immediate fire detection and intervention, avoiding delays associated with external or portable solutions. Automatic Activation for Quick Response Automatic activation enables rapid, autonomous fire suppression, which is critical in unmanned or hard-to-reach areas, minimizing damage and preventing fire spread. Broader Operational Benefits Automated fire suppression protects assets and personnel, reduces insurance claims, and supports business continuity by preventing costly downtime through early fire control.

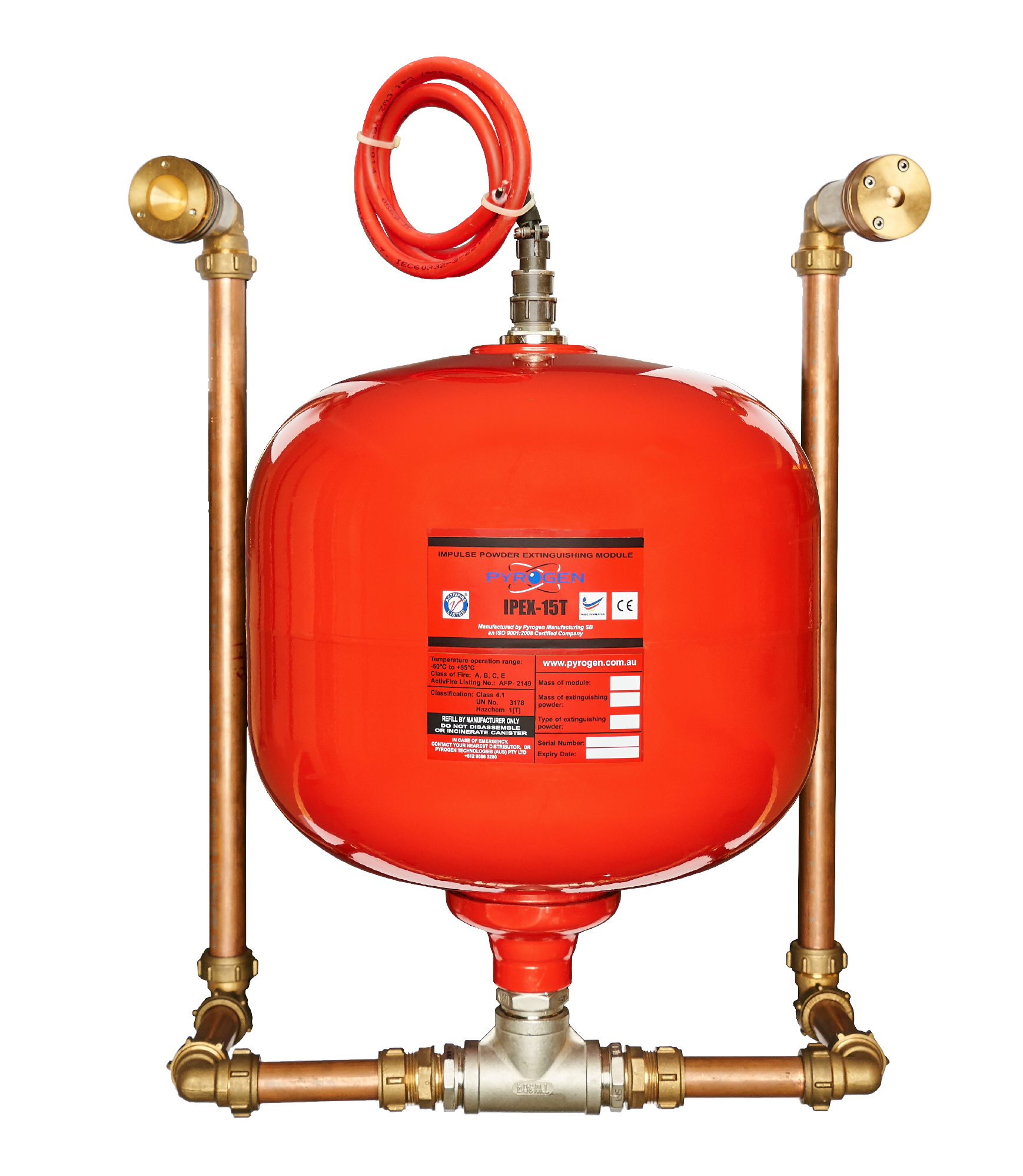

An effective fire suppression system for rolling stock depots must act quickly and reliably address both Class A and Class C fire risks. The key is early fire detection and rapid agent deployment to extinguish or contain the fire before it spreads. This approach prioritizes life safety by minimizing exposure to flames and toxic smoke, allowing for safer, more orderly evacuations if needed. It also significantly reduces property damage and operational downtime, enabling faster recovery and lowering economic losses. IPEX IPEX fire suppression is a critical safety system to ensure operators and equipment remain safe. Our systems can be installed directly inside the engine compartment, close to the high-risk area. Our systems are easily to retrofit on your fleet. This 24/7 automatic system reduces the risk as the fire can happen at any time including remote locations. Once a fire is detected, the fire is quickly suppressed minimizing damage and downtime. IPEX fire suppression system protects the machinery compartments including the engine bay of the vehicles that we protect include mining vehicles, military vehicles, and forestry machinery such bunchers, skidders, loaders, harvesters, shovels, and loggers as to name a few. EXA For general mobile equipment such as generator sets, EXA condensed aerosol systems can be used to provide comprehensive protection. EXA generators are compact, lightweight, and self-contained, making them particularly suitable for integration into mobile equipment such as gen sets. The minimal space requirements and ability to function independently without external piping or water supply simplify installation and maintenance in mobile or confined environments. EXA generators perform reliably across a range of environmental conditions commonly encountered by mobile equipment, including vibrations, temperature fluctuations, and confined spaces. This robustness makes them ideal for safeguarding gen sets that operate in diverse and sometimes remote locations. Reach out to us to learn more.