Power transformers, particularly those filled with mineral oil for insulation and cooling, pose significant fire hazards. When the insulating liquid is heated beyond its flash point, it can ignite, resulting in intense fires and potentially explosive events. Such incidents can cause extensive damage to the transformer and surrounding equipment and infrastructure.

Transformers serve a critical role by connecting medium-voltage generators to high-voltage power systems. Although transformer fires are relatively rare, their consequences are often severe—leading to total equipment loss, collateral damage, and prolonged outages. These risks are especially concerning in transformer rooms that were originally designed for staffing but are now often unattended, further increasing vulnerability in the event of fire.

Overheating Often caused by insulation failure or inadequate cooling, overheating can lead to internal component failure and ultimately fire. Short Circuits Electrical faults allowing uncontrolled current flow generate excessive heat, which can ignite internal components or nearby flammable materials. Oil Leaks Mineral oil leaks present a major fire hazard. If the oil comes into contact with hot surfaces or sparks, it can ignite and escalate quickly. Lightning Strikes Although less common, lightning can cause electrical surges, insulation breakdowns, and fires, particularly in exposed outdoor installations.

Ventilation Openings While necessary for thermal regulation, ventilation compromises the integrity of fire suppression systems that require sealed enclosures for optimal performance. Multi-Class Fire Hazards Transformer fires may involve a mix of Class A (combustibles), Class B (flammable liquids), and Class C (electrical equipment). Fire suppression systems must be rated and certified accordingly. Remote Locations Substations in isolated areas can complicate the installation, maintenance, and rapid activation of fire suppression systems due to limited access. Unmanned Facilities With no on-site personnel, early fire detection and response may be delayed, increasing the potential for major damage. Unmanned substations are also more vulnerable to risks such as vandalism or unauthorized access.

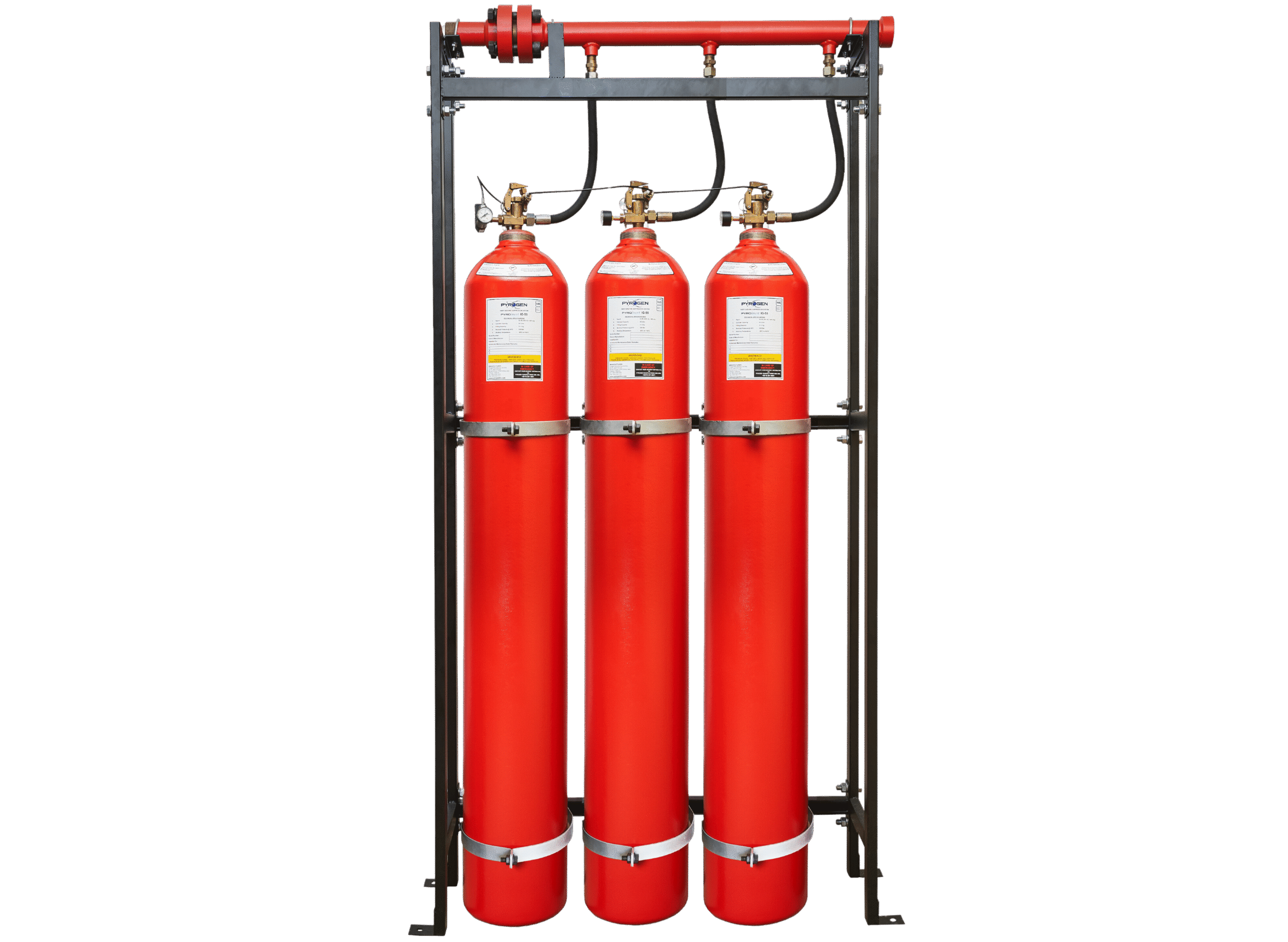

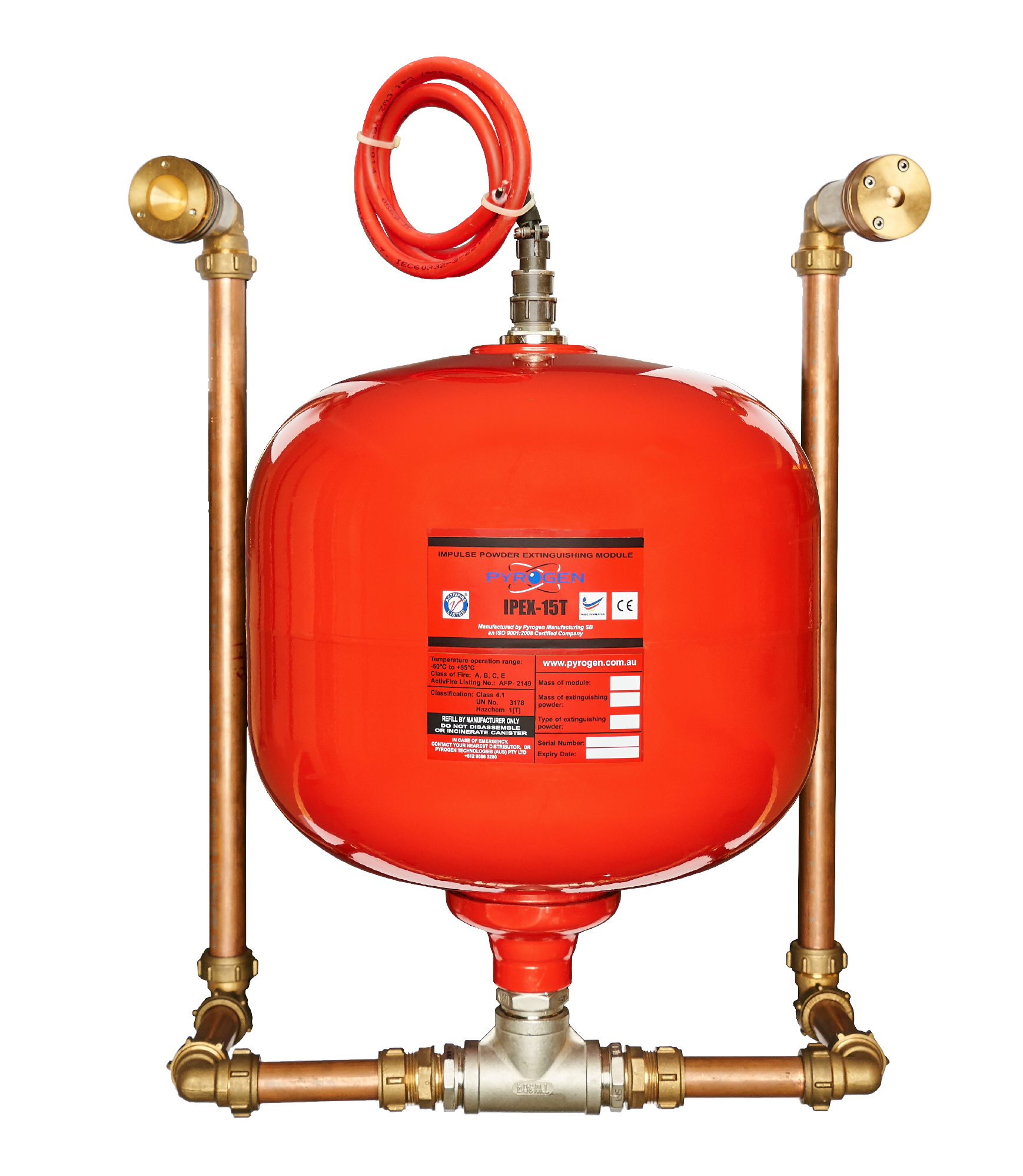

For fully enclosed transformer rooms, EXA condensed aerosol system is an effective fire suppression solution designed specifically for enclosed transformer rooms. It releases a fine aerosol composed of solid particles suspended in a gas that rapidly interrupts the chemical chain reactions of combustion. This quick and efficient suppression method prevents fire escalation in the confined, high-risk environment of transformer enclosures. Due to its compact, self-contained units, EXA generators are suitable for integration without requiring extensive modifications or additional piping. For transformer rooms that are semi-enclosed or have open configurations, the IPEX impulse powder system delivers powerful and quick fire suppression by discharging proprietary dry chemical powder rapidly. This impulse action disperses the suppressant effectively over large confined volumes, where gaseous or aerosol agents may be less effective due to ventilation or airflow. The impulse powder interrupts combustion processes through chemical inhibition, quickly controlling fires at their onset. IPEX systems are designed for durability and ease of use in challenging environments around transformers, making them suitable for installations in outdoor transformer or semi-open transformer rooms, where rapid suppression and broad coverage are essential. For a clean agent alternative for fully enclosed transformer rooms, PyroInert inert gas systems provide clean, reliable fire suppression that extinguishes fires without leaving residues or causing mechanical damage, thus ensuring the protection of critical assets and minimizing downtime. PyroInert systems are especially well-suited for enclosed transformer rooms housing sensitive electrical equipment because the inert gases are colorless, odorless, non-corrosive, and electrically non-conductive. Reach out to us to learn more.