Fire protection in the mining industry is inherently complex due to a combination of high-risk factors, vast operational scales, and challenging environmental conditions. Mines—whether surface or underground—are environments where fire hazards are ever-present and can have severe, even catastrophic, consequences. The presence of combustible materials, heavy machinery, pressurized systems, and flammable liquids or gases significantly heightens the likelihood of fire or explosion incidents. These risks are compounded by the remoteness of most mining operations, where response times may be delayed and access to emergency services limited.

The diversity of mining processes—from drilling, blasting, crushing, and conveying to processing and refining—introduces multiple ignition points across the operation. Each step involves the use of high-powered electrical and mechanical systems, creating numerous opportunities for heat generation, friction, and energy discharge. Add to this the storage and handling of fuels, lubricants, explosives, and reactive chemicals, and the overall fire risk profile becomes even more complex.

Mining vehicle fleets—including haul trucks, loaders, excavators, and drills—are essential to day-to-day operations and typically function under some of the most extreme conditions found in any industry. These vehicles are regularly exposed to high levels of dust, heat, continuous vibration, and abrasive terrain, all of which contribute to accelerated wear and tear on electrical systems, hydraulic components, and engines. The engine compartments, in particular, are high-risk zones for fire due to the combination of flammable fluids, high temperatures, and confined space.

Given these realities, early fire detection and fast-acting suppression systems are not optional—they are critical. A minor ignition left undetected can quickly grow into a large-scale fire capable of damaging or destroying multimillion-dollar machinery and infrastructure. Just as importantly, the safety of operators and on-site personnel is at serious risk in such events, especially when evacuation or firefighting options are constrained by the physical environment.

Modern fire protection strategies in the mining sector must be robust, automated, and tailored to individual risk areas. Systems should be designed to withstand dust, moisture, shock, and temperature extremes while providing reliable performance without frequent maintenance. Engine compartments, electrical cabinets, processing control rooms, and fuel storage areas are key protection zones that benefit from the integration of fire detection and suppression technologies.

In addition to mobile assets, other vital infrastructure such as electrical rooms, UPS (uninterruptible power supply) rooms, substations, and machinery zones also require comprehensive fire protection. Implementing robust suppression systems and well-defined emergency response plans is key to maintaining a safe working environment, minimizing downtime, and ensuring business continuity.

A well-executed fire protection strategy in the mining sector not only reduces operational risk but also demonstrates a strong commitment to the safety of personnel and the resilience of critical infrastructure.

Preserve the core of your business operations by safeguarding critical assets and human lives from potential fire hazards.

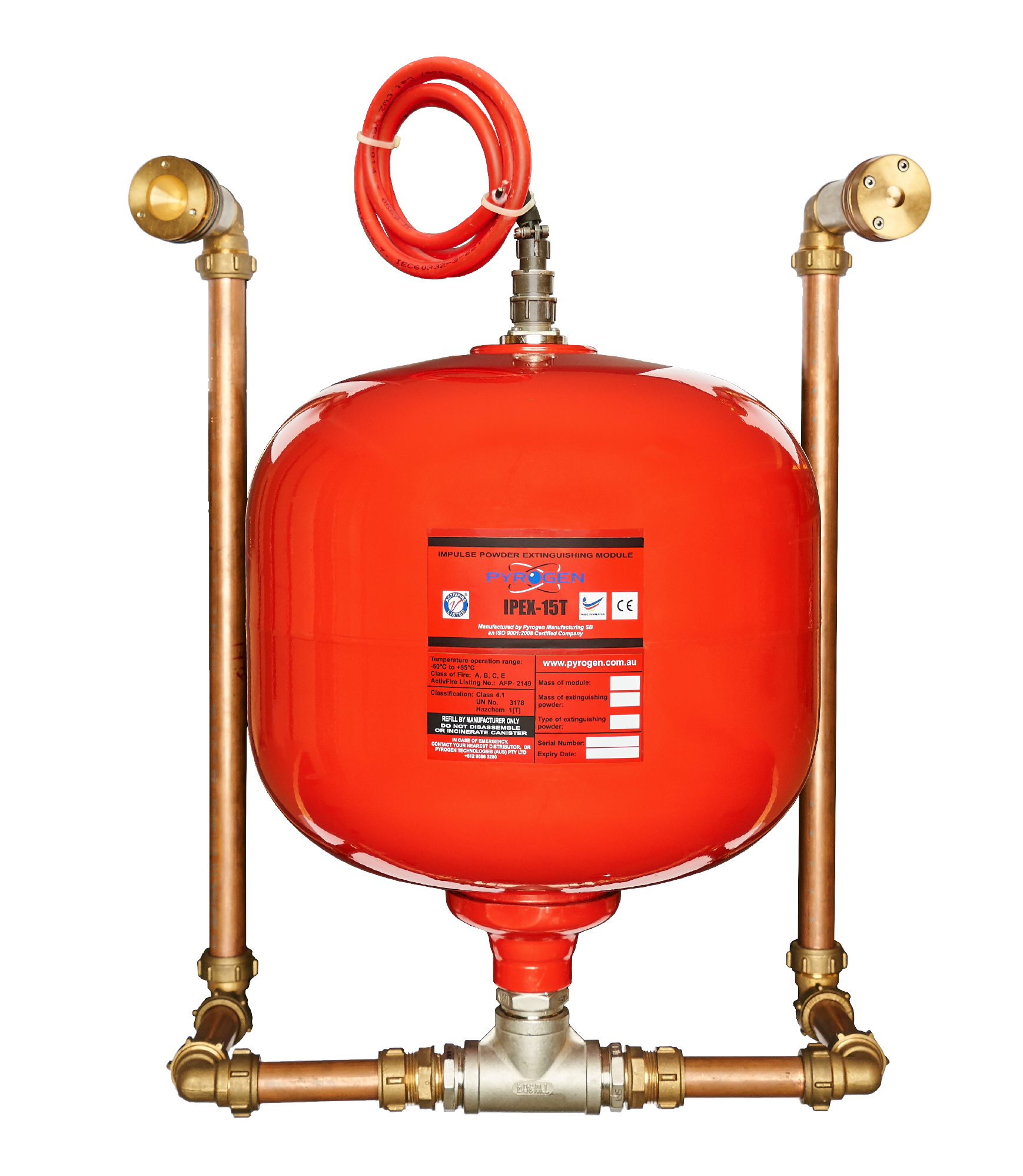

With Pyrogen’s fire suppression systems, your operations can run seamlessly with minimal disruptions from fire incidents and your employees can work in a safe environment.

Pyrogen’s range of fire suppression systems are certified to international fire standards, environmentally friendly and manufactured with stringent quality standards.