The oil and gas industry operates in one of the highest-risk environments for fire and explosion incidents. Due to the presence of highly flammable gases, vapors, and chemicals—such as hydrogen sulfide—fire risk mitigation is a top operational priority. These hazardous substances may be released from wells, storage tanks, trucks, shale shakers, and other production equipment during routine operations.

Ignition sources in these settings are numerous and varied, ranging from static electricity and open flames to lightning, cigarettes, hot surfaces, welding activities, and frictional heat. When heat or ignition sources are in close proximity to combustible liquids, the potential for fire is significantly elevated, creating a high-risk profile for both personnel and assets.

Given the widespread use of volatile chemicals and materials in extraction, processing, and refining operations, robust fire protection strategies are essential. Effective fire risk management plays a critical role in safeguarding personnel, minimizing operational downtime, and protecting high-value infrastructure.

Compounding the challenge is the typically congested layout of oil and gas facilities. These complex environments often contain dense networks of piping, tanks, and processing equipment stacked across multiple levels, leaving limited room for access and firefighting. The close proximity of heat-generating machinery and combustible substances further increases fire propagation risk.

Given the widespread use of volatile chemicals and materials in extraction, processing, and refining operations, robust fire protection strategies are essential. Effective fire risk management plays a critical role in safeguarding personnel, minimizing operational downtime, and protecting high-value infrastructure.

Compounding the challenge is the typically congested layout of oil and gas facilities. These complex environments often contain dense networks of piping, tanks, and processing equipment stacked across multiple levels, leaving limited room for access and firefighting. The close proximity of heat-generating machinery and combustible substances further increases fire propagation risk.

Oil and gas facilities are inherently hazardous, and their remote and often harsh operating environments add further complexity to fire protection. In such high-risk areas, fire detection and suppression systems must demonstrate exceptional reliability, resilience, and performance. These systems should be certified by recognized third-party organizations to ensure they meet stringent safety and operational standards.

Despite the implementation of fire safety programs, fire incidents in the oil and gas industry remain a persistent threat. Fires frequently originate in machinery and engine rooms, electrical control systems, or locations where flammable gases, vapors, or chemicals are present near hot work zones or energized surfaces. Common ignition points include areas where static discharge, frictional heat, or welding sparks can come into contact with combustible materials.

In many cases, these fire-prone areas are difficult to access, especially in offshore platforms or remote extraction sites. This makes early detection and rapid suppression critical, as delayed response increases the likelihood of fire escalation, asset loss, production downtime, and potential injury or fatality.

As such, fire protection solutions in the oil and gas industry must be not only fast-acting and highly effective but also capable of operating under the most demanding environmental conditions. A proactive and comprehensive fire safety approach is essential to ensure business continuity, regulatory compliance, and—most importantly—the safety of the workforce.

Preserve the core of your business operations by safeguarding critical assets and human lives from potential fire hazards.

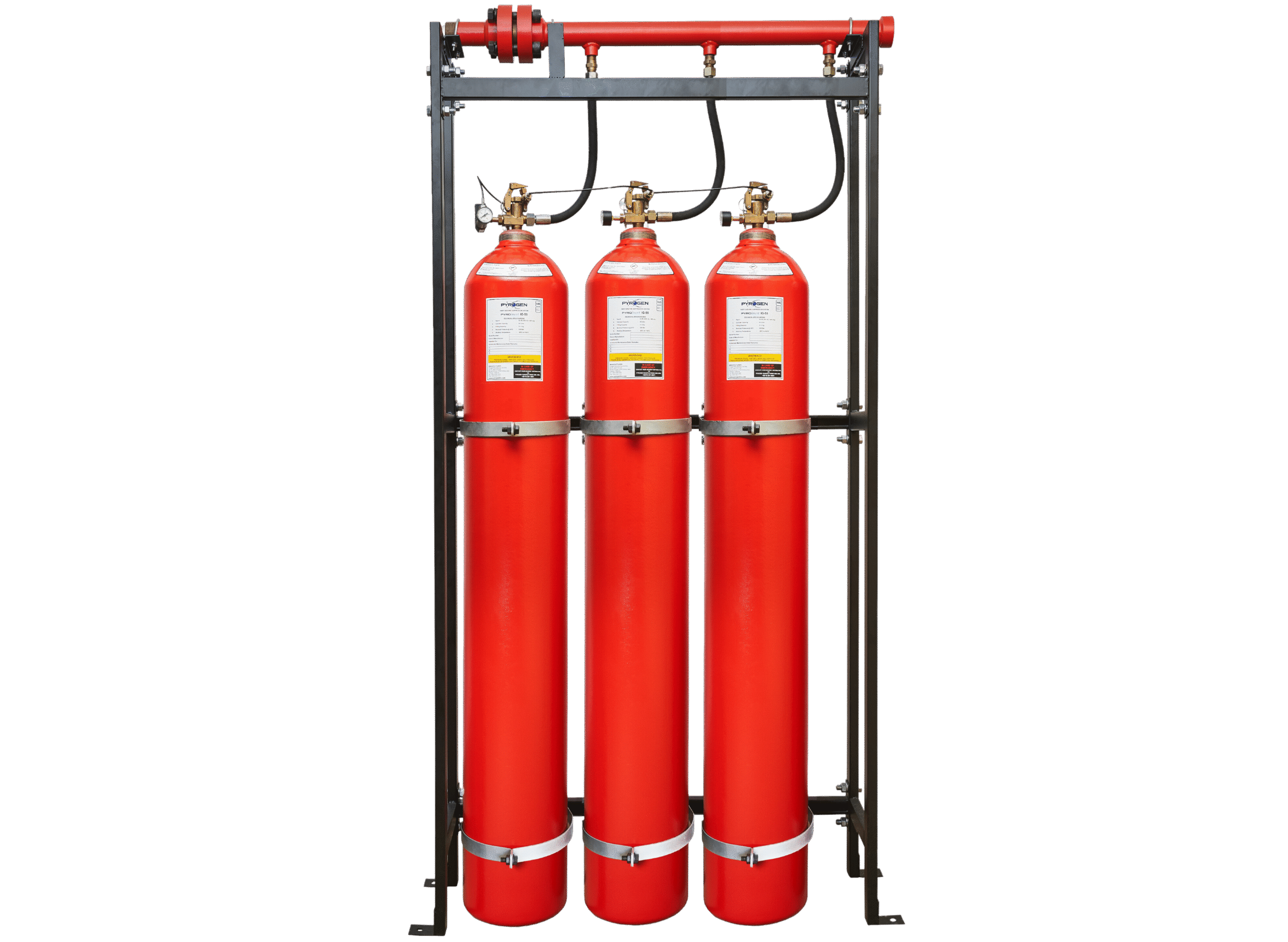

With Pyrogen’s fire suppression systems, your operations can run seamlessly with minimal disruptions from fire incidents and your employees can work in a safe environment.

Pyrogen’s range of fire suppression systems are certified to international fire standards, environmentally friendly and manufactured with stringent quality standards.