Modern storage facilities—such as warehouses, distribution centers, and large-scale retail hubs—are critical to supply chain efficiency and are typically designed with just-in-time logistics in mind. As a result, these facilities often operate under tight schedules, with high inventory turnover and dense storage configurations. From an operational standpoint, they represent some of the most valuable assets to protect against fire due to the potential impact on logistics, supply continuity, and business operations.

However, these facilities also present a range of inherent fire risks. Technical faults are among the leading contributors—arising from electrical equipment such as switchgear, control cabinets, electric motors, transformers, and battery systems. Additional fire hazards include cooling systems used in refrigerated and frozen storage areas, defrosters, and maintenance-related activities such as welding and cutting. The presence of flammable packaging materials, high racking systems, and continuous movement of goods and machinery further increase fire load and complexity.

Due to the large volumes of combustible materials and the configuration of storage systems, fires in these environments can escalate rapidly, making early detection and rapid suppression absolutely critical.

According to the National Fire Protection Association (NFPA), the primary causes of fires in storage facilities include intentional acts (arson), followed by malfunctions in electrical equipment such as wiring, circuit breakers, control panels, and transformers. Additional ignition sources include material handling equipment like forklifts and spontaneous or accidental chemical reactions between incompatible substances. Furthermore, materials such as hot-shrink packaging films, wooden pallets, and irradiated goods can significantly contribute to the spread and intensity of a fire once ignited.

These large-scale “big box” environments present unique and complex challenges for both fire suppression system designers and emergency responders. High ceiling clearances, complex layouts, obstructed access, and the vertical storage of goods complicate both fire detection and firefighting efforts.

The most reliable and efficient strategy for protecting such facilities from rapidly developing fires is the integration of a well-engineered, pre-emptive fire suppression system.

Preserve the core of your business operations by safeguarding critical assets and human lives from potential fire hazards.

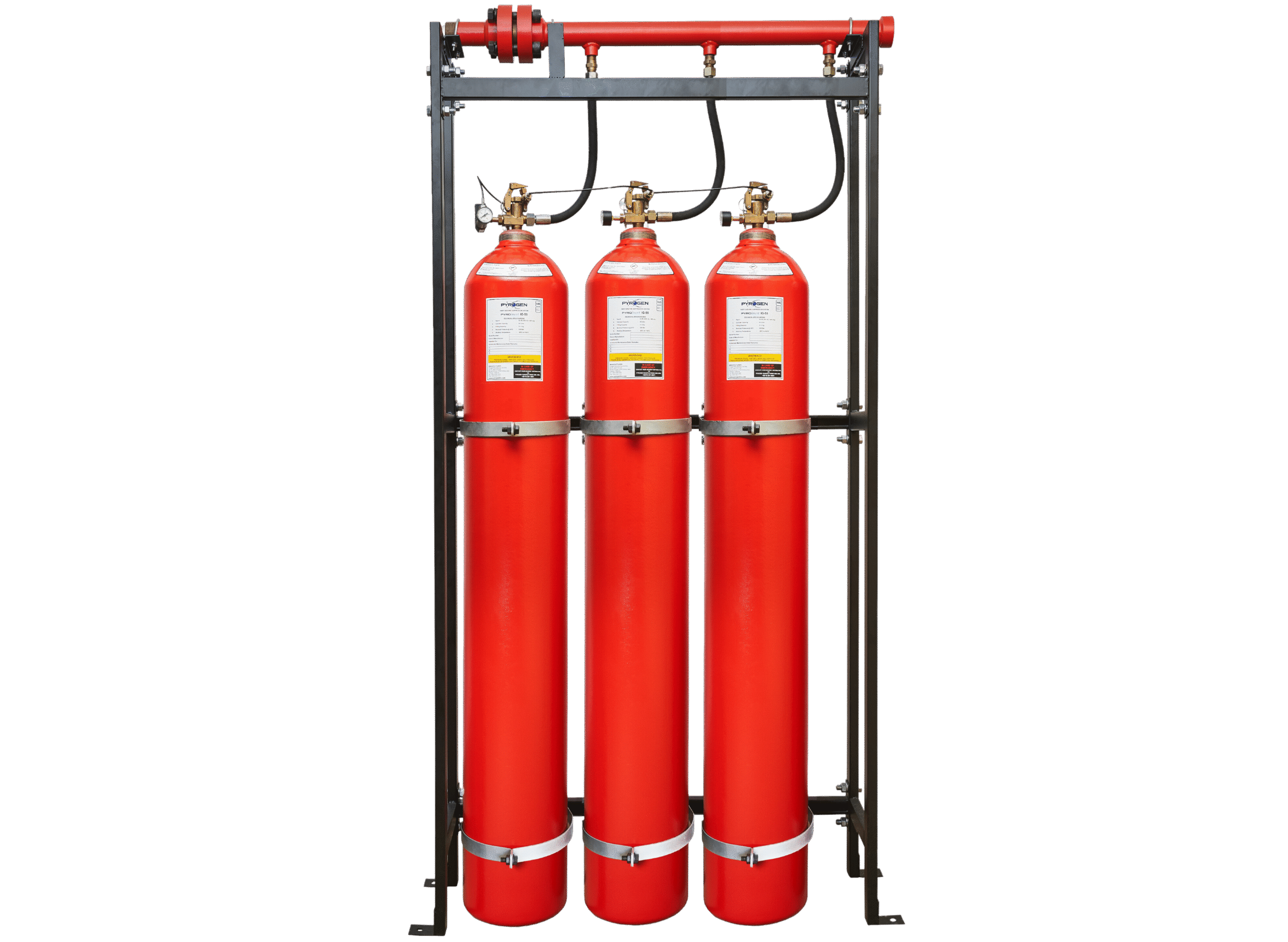

With Pyrogen’s fire suppression systems, your operations can run seamlessly with minimal disruptions from fire incidents and your employees can work in a safe environment.

Pyrogen’s range of fire suppression systems are certified to international fire standards, environmentally friendly and manufactured with stringent quality standards.